"Call our office to book this specialized training and arrange payment. The cost of the course is $600 per participant."

🔍 Click to Expand: ACTI LEEA Basic Rigging Training Overview

📌 ACTI LEEA Basic Rigging Training Overview

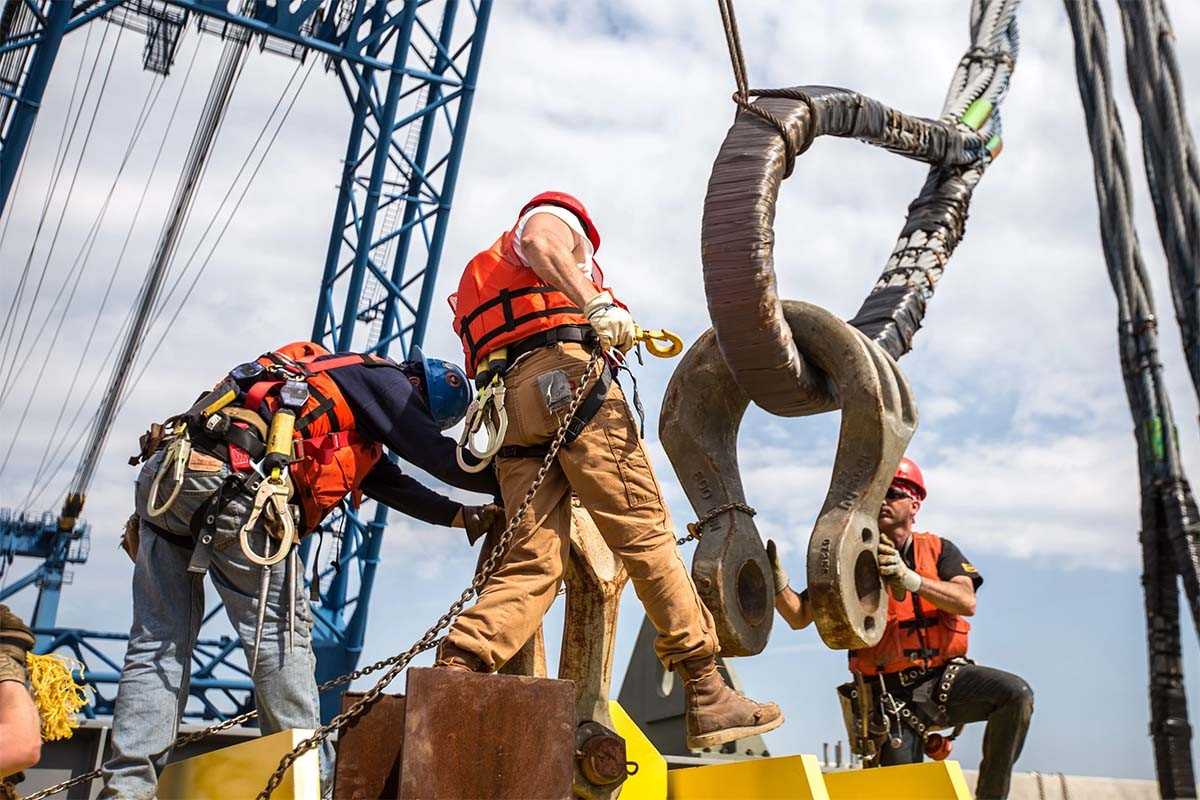

The ACTI LEEA Basic Rigging Training Program is designed to provide workers with the fundamental knowledge and skills necessary to perform safe rigging and lifting operations. This training follows the Lifting Equipment Engineers Association (LEEA) standards, ensuring compliance with Occupational Health & Safety (OH&S) regulations, CSA standards, and industry best practices.

Participants will learn to identify rigging equipment, calculate load weights, select proper slings, understand lifting angles, inspect rigging gear, and follow best practices for safe lifting operations. The course covers lifting theory, center of gravity, hardware usage, below-the-hook devices, and crane communication.

📌 Course Structure

- Duration: 16 hours (varies based on participant experience).

- Delivery Method: Theory-based presentations, discussions, written exams, and hands-on practical evaluations.

- Assessment: Written exam (minimum 80% pass mark) and practical demonstration of rigging skills.

📌 Key Learning Modules

🔹 1. Legislation & Safety Standards

- LEEA regulations, OH&S standards, CSA compliance, and employer/worker responsibilities.

- Understanding legal obligations and best practices for rigging operations.

🔹 2. Load Weight Calculation & Center of Gravity

- Techniques for estimating and verifying load weights.

- Understanding the center of gravity and its impact on lifting stability.

- Methods for safely balancing and positioning loads.

🔹 3. Sling Angles, Hitches & Stress Factors

- Understanding sling configurations: vertical, choker, and basket hitches.

- Load angle stress and how sling angles affect lifting capacity.

- Best practices for using multiple sling configurations.

🔹 4. Types of Rigging Equipment

- Identification and safe use of synthetic slings, wire rope slings, and chain slings.

- Inspection procedures, load capacity, and maintenance of rigging hardware.

- Proper storage, usage, and rejection criteria.

🔹 5. Hardware & Below-the-Hook Lifting Devices

- Inspection and safe use of shackles, hooks, eyebolts, turnbuckles, master links, and spreader bars.

- Understanding below-the-hook devices such as lifting beams, clamps, magnets, and drum lifters.

- Rigging gear inspections and criteria for removing defective equipment from service.

🔹 6. Crane Considerations & Communication

- Overview of crane types and safe lifting procedures.

- Hand signals and voice communication for directing crane movements.

- Load stability, swing control, and exclusion zone management.

🔹 7. Common Hazards & Risk Mitigation

- Identifying rigging hazards such as unstable loads, overhead power lines, and pinch points.

- Preventing load shifting, equipment failures, and worker injuries.

- Emergency response planning and best practices.

📌 Why Choose ACTI LEEA Basic Rigging Training?

- ✅ Regulatory Compliance: Meets LEEA, CSA, and OH&S rigging safety requirements.

- ✅ Hands-On Learning: Practical exercises to reinforce rigging skills.

- ✅ Industry-Specific Training: Designed for construction, industrial, and heavy-lifting environments.

- ✅ Certification & Tracking: Automated learner progress tracking with instant certification upon completion.

📌 Getting Started

- Enroll in Your Course – Choose the ACTI LEEA Basic Rigging Training program and begin your training.

- Complete Training – Engage with interactive learning, written assessments, and instructor-led sessions.

- Earn Certification – Upon successful completion, receive your ACTI LEEA Basic Rigging Certification.

Ready to get started? Enroll today and enhance your rigging safety and compliance knowledge!

"Call our office to book this specialized training and arrange payment. The cost of the course is $1100 per participant."

🔍 Click to Expand: ACTI LEEA Advanced Rigging Training Overview

📌 ACTI LEEA Advanced Rigging Training Overview

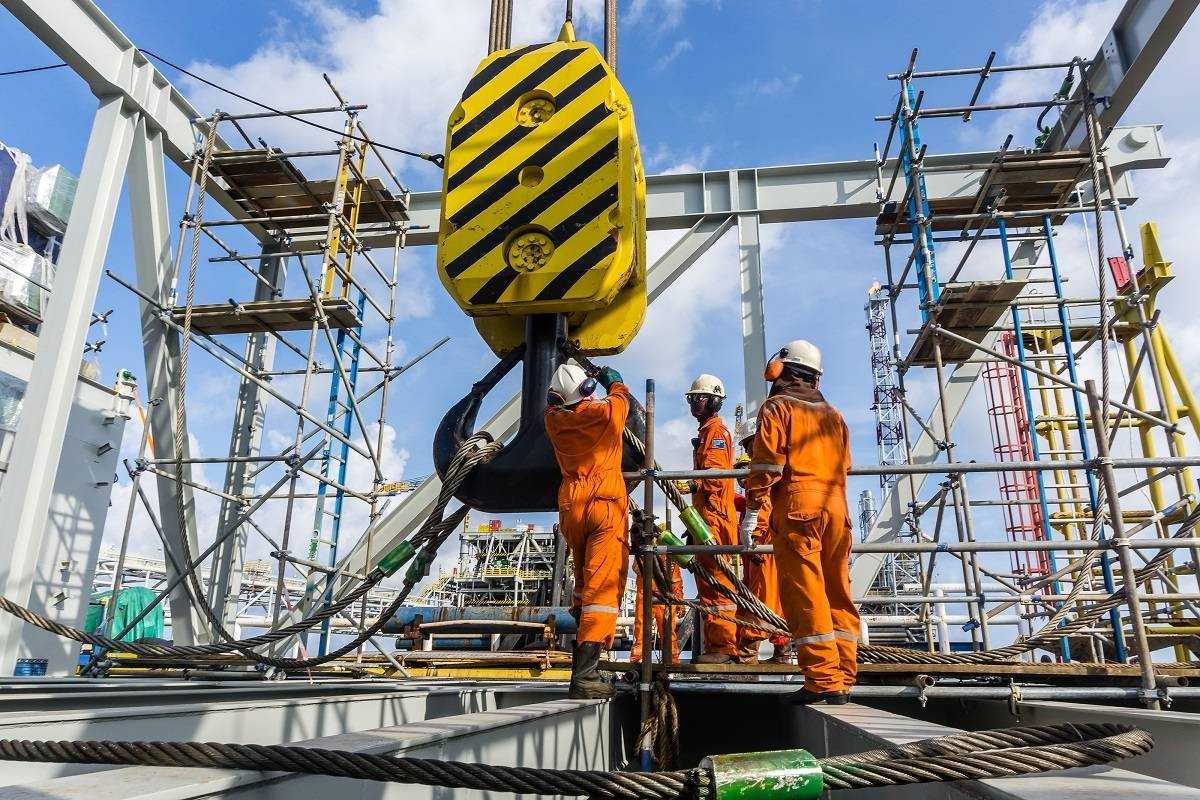

The ACTI LEEA Advanced Rigging Training Program is designed to provide experienced riggers with the in-depth knowledge and technical skills required for complex and critical lifting operations. This training follows the Lifting Equipment Engineers Association (LEEA) standards, ensuring compliance with Occupational Health & Safety (OH&S) regulations, CSA standards, and industry best practices.

Participants will learn advanced load control techniques, rigging calculations, multi-crane lifts, critical lift planning, and specialized rigging gear use. The course covers lifting dynamics, stability factors, crane communication, engineered lifts, and risk assessments.

📌 Course Structure

- Duration: 40 hours (varies based on participant experience).

- Delivery Method: Instructor-led presentations, group discussions, written exams, and hands-on practical evaluations.

- Assessment: Written exam (minimum 80% pass mark) and practical demonstration of advanced rigging skills.

📌 Key Learning Modules

🔹 1. Legislation & Safety Standards

- LEEA regulations, OH&S standards, CSA compliance, and employer/worker responsibilities.

- Review of legal requirements for high-risk rigging operations.

🔹 2. Load Weight Estimation & Center of Gravity

- Advanced techniques for determining load weight and balance.

- Calculating center of gravity and adjusting rigging configurations accordingly.

🔹 3. Sling Angles, Stress Factors & Multi-Leg Bridles

- Understanding sling angle stress and load distribution.

- Determining the effects of different hitch configurations.

- Using rigging cards for accurate load calculations.

🔹 4. Rigging Hardware & Below-the-Hook Devices

- Selection, inspection, and application of shackles, hooks, eyebolts, turnbuckles, and spreader bars.

- Proper use of lifting beams, clamps, magnets, and custom-engineered lifting devices.

🔹 5. Load Stability & Advanced Rigging Applications

- Managing stability during lifting, lowering, and moving loads.

- Understanding drifting, tailing, and turning loads safely.

🔹 6. Multi-Crane Lifts & Critical Lift Planning

- Planning and executing tandem crane lifts.

- Understanding crane dynamics and capacity considerations.

- Risk assessments and contingency planning for high-risk lifts.

🔹 7. Communication & Signal Person Responsibilities

- Effective use of hand signals, radio communication, and crane signaling.

- Directing crane and load movement safely in various environments.

🔹 8. Crane Operations & Load Control Techniques

- Understanding crane limitations, load charts, and dynamic loading factors.

- Use of taglines, come-alongs, and drift control techniques.

📌 Why Choose ACTI LEEA Advanced Rigging Training?

- ✅ Regulatory Compliance: Meets LEEA, CSA, and OH&S advanced rigging safety requirements.

- ✅ Hands-On Learning: Practical exercises to reinforce critical rigging skills.

- ✅ Industry-Specific Training: Designed for high-risk lifting in construction, industrial, and heavy-lifting sectors.

- ✅ Certification & Tracking: Automated learner progress tracking with instant certification upon completion.

📌 Getting Started

- Enroll in Your Course – Choose the ACTI LEEA Advanced Rigging Training program and begin your training.

- Complete Training – Engage with interactive learning, written assessments, and instructor-led sessions.

- Earn Certification – Upon successful completion, receive your ACTI LEEA Advanced Rigging Certification.

Ready to get started? Enroll today and take your rigging expertise to the next level!

Prerequisite for this training is LEEA / ACTI Advanced Rigging

"Call our office to book this specialized training and arrange payment. "

🔍 Click to Expand: Lift Director Training Overview

The **ACTI Lift Director Training Program** is designed to equip individuals with the **knowledge and skills necessary to oversee crane and lifting operations safely and effectively**. This training aligns with **Alberta OH&S regulations, ASME P30.1 standards, and industry best practices**, ensuring compliance and operational efficiency.

Participants will learn how to **plan, supervise, and execute lifting operations while managing risks, ensuring crew safety, and maintaining regulatory compliance**. The course covers **lift categorization, risk assessment, exclusion zones, crane inspections, and emergency procedures**.

📌 Key Learning Modules:

- Regulatory Standards & Compliance: Understanding OH&S requirements, ASME P30.1, and employer responsibilities.

- Lift Planning & Risk Assessment: Developing and implementing standard and critical lift plans.

- Crane Inspections & Equipment Maintenance: Performing pre-use, routine, and periodic inspections to ensure compliance.

- Exclusion Zones & Safety Protocols: Implementing safe work procedures to protect workers and prevent unauthorized access.

- Communication & Coordination: Establishing clear communication methods between crane operators, signal persons, and ground crews.

- Emergency Preparedness & Incident Response: Developing contingency plans and responding to lift-related emergencies.

✅ Upon Completion:

Upon successfully completing the **ACTI Lift Director Training Program**, participants will be able to:

- ✅ **Understand and apply** Alberta OH&S regulations, ASME P30.1, and CSA standards related to lift planning and supervision.

- ✅ **Categorize lifts** as standard or critical and develop appropriate lift plans.

- ✅ **Conduct crane inspections** and ensure compliance with pre-use and periodic inspection requirements.

- ✅ **Establish and enforce exclusion zones** to prevent unauthorized personnel from entering high-risk areas.

- ✅ **Coordinate lift activities** and maintain effective communication between all personnel involved.

- ✅ **Develop and execute emergency action plans** for equipment failures, environmental hazards, and personnel safety incidents.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical skills evaluation.

Participants who meet all course requirements will receive an **ACTI Lift Director Certification**, recognized across **Canada**, ensuring they are qualified to oversee and manage **safe and efficient lifting operations in industrial and construction environments**.